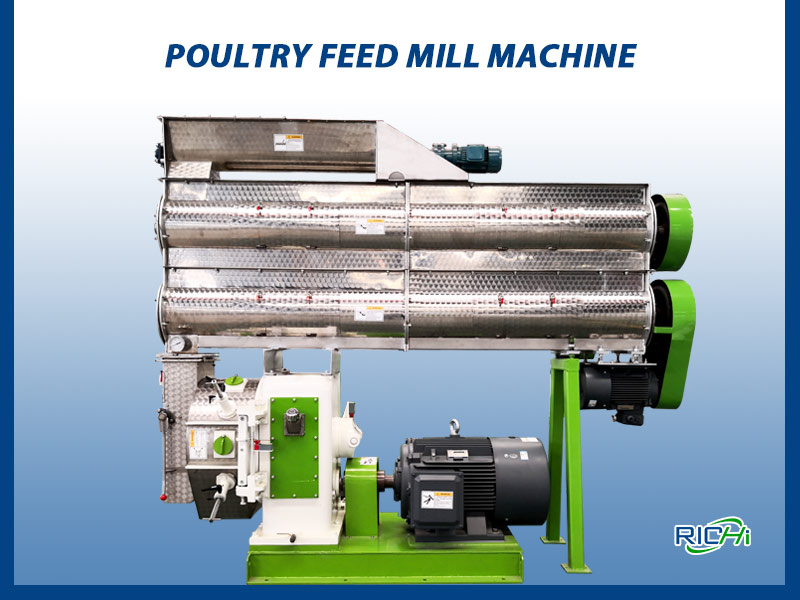

Key Components of a Poultry Feed Mill Machine

Poultry farming is a vital sector in the agricultural industry, and ensuring the nutritional needs of the birds are met is crucial for their growth and productivity. A poultry feed mill machine plays a vital role in producing nutritious and balanced feed for poultry. It is designed to crush and mix different ingredients, transform them into pellets, and enhance the overall quality of the feed. In this article, we will explore the key components of a poultry feed mill machine and their significance in the feed milling process.

Understanding the Feed Milling Process

The feed milling process involves several stages, starting from the raw materials to the final poultry feed. The process begins with the grinding or crushing of raw materials, followed by the blending or mixing of various ingredients. The mixed ingredients are then transformed into pellets using a pellet mill. Afterward, the pellets undergo cooling and sifting to enhance their quality. Finally, the finished feed is packaged and stored for distribution.

Importance of Granulation in Poultry Feed

Granulation is a crucial step in the feed milling process as it determines the size and shape of the feed particles. Proper granulation ensures uniformity in the size of the feed particles, allowing for consistent intake and digestion by poultry. Additionally, granulation helps to improve pellet durability, reducing wastage and improving feed efficiency. It also enhances the flowability of the feed, making it easier to handle and distribute.

Hammer Mills: Crushing the Raw Materials

Hammer mills are essential machines in the poultry feed mill as they are used to crush or grind various raw materials into smaller particles. These raw materials may include grains, cereals, oilseeds, and other ingredients. The hammer mill’s high-speed rotating blades impact the materials, breaking them down into smaller sizes suitable for further processing.

Mixer Machines: Blending the Ingredients

Mixer machines play a vital role in the feed milling process by ensuring the uniform blending of different ingredients. The pellet machine comes in various configurations, such as horizontal or vertical mixers, and are equipped with rotating blades or paddles. The mixing process ensures that each batch of feed contains the required proportions of ingredients, providing a balanced and nutritious feed for poultry.

Pellet Mills: Transforming Feed Ingredients

Pellet mills are the heart of the feed milling process, where the blended ingredients are transformed into compact pellets. These machines use heat, pressure, and moisture to bind the feed particles together. The pellets are then extruded through dies of different sizes, resulting in uniform pellets suitable for poultry consumption. Pellet mills are designed to produce feed pellets of various sizes and densities, catering to different poultry species and their nutritional requirements.

Cooling and Sifting: Enhancing Feed Quality

After the pelletization process, the pellets need to be cooled and sifted to enhance their quality. Cooling the pellets helps to reduce moisture content, making them more stable and resistant to spoilage. Sifting removes any fines or irregularly shaped pellets, ensuring a consistent and high-quality feed. These processes improve the shelf life of the feed and prevent clogging or blockages in the feeding systems.

Packaging and Storage of Poultry Feed

Packaging and storage are crucial steps in ensuring the quality and safety of the poultry feed. The finished feed is packaged in bags or bulk containers, with proper labeling for easy identification. The packaging materials should be durable and moisture-resistant to protect the feed from spoilage. Additionally, proper storage conditions, such as cool and dry environments, should be maintained to prevent the growth of mold or bacteria.

Maintenance and Safety Measures for Feed Mill Machines

Regular maintenance of feed mill machines is essential to ensure their optimal performance and longevity. This includes routine inspections, cleaning, and lubrication of the machine components. Safety measures, such as installing guards and emergency stop buttons, should be in place to prevent accidents and injuries. Proper training and supervision of operators are also crucial to ensure safe operation and prevent any mishaps.

Related post: https://richipelletizer.com/poultry-feed-mill-machine/

Choosing the Right Poultry Feed Mill Machine

Selecting the right poultry feed mill machine is crucial for efficient feed production. Factors such as production capacity, energy efficiency, ease of operation, and maintenance should be considered. It is essential to choose a machine that can handle the desired feed ingredients, produce the required pellet size, and meet the specific needs of the poultry farm. Consulting with experts and considering the reputation and reliability of the manufacturer can help in making an informed decision.

Ensuring the production of high-quality and nutritious feed is essential for the success of any poultry farm. A well-designed poultry feed mill machine, equipped with the key components discussed in this article, can greatly contribute to achieving this goal. By understanding the feed milling process and selecting the right machine, poultry farmers can ensure the health and productivity of their birds while optimizing their feed production efficiency.