In the age of environmental consciousness, wood pellet machinery has emerged as a cornerstone in the renewable energy sector. Wood pellets, crafted from compressed biomass, are pivotal in reducing carbon footprints and are increasingly used in heating systems and power plants worldwide. The demand for efficient and reliable wood pellet machines has surged, sparking significant developments in this niche market.

This detailed examination delves into the wood pellet machinery industry, exploring its growth, the pivotal role played by leading manufacturers, and providing insights into making informed choices when selecting a machine, with an emphasis on the capabilities and achievements of Richi Manufacture.

Industry Overview and Recent Trends (2019-2023)

From 2019 to 2023, the wood pellet machinery industry has witnessed remarkable growth, both in terms of technological advancements and market expansion. In 2019, the market was valued at around $7 billion, steadily growing despite the global challenges posed by the COVID-19 pandemic.

The resilience of the industry was partly due to the increased focus on sustainable energy sources, as nations sought alternatives to fossil fuels.

The year 2020 saw a continued rise in demand, particularly in Europe and North America, where governmental policies favoring green energy significantly contributed to market growth. The Asia-Pacific region also showed potential, with emerging economies beginning to explore biomass as a viable energy source.

2021 marked a year of technological innovation, with manufacturers introducing more efficient and automated machinery. This advancement was critical in reducing operational costs and enhancing production efficiency, making wood pellets a more competitive energy source.

By 2022 and 2023, the industry’s market value had soared, driven by the heightened global emphasis on carbon neutrality and renewable energy. The period saw a surge in investments in renewable energy infrastructure, further cementing wood pellets’ position in the global energy matrix.

Leading Manufacturers in the Wood Pellet Machine Industry

This period of growth and innovation has been shaped by key manufacturers who have significantly contributed to the industry’s evolution:

Andritz Group (Austria): A global leader in wood pellet technology, Andritz offers a range of machines known for their efficiency and reliability. They have consistently set standards in the industry, supplying machinery to some of the world’s largest pellet production facilities.

CPM (California Pellet Mill) (USA): With a reputation for durability and versatility, CPM’s machinery is designed to handle a variety of biomass materials, making them a popular choice worldwide.

Bühler Group (Switzerland): At the forefront of technological innovation, Bühler’s machines are renowned for their energy efficiency and high-quality pellet production capabilities.

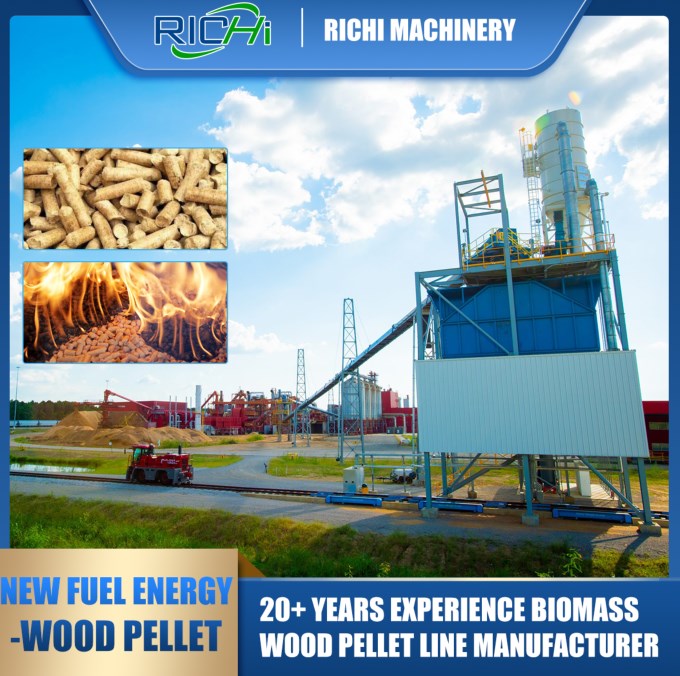

Richi Machinery (China): Located in Henan Province, Richi Machinery has distinguished itself with its focus on technological innovation, quality, and customer-centric approach. Their machinery is designed for efficiency, sustainability, and ease of use, offering custom solutions tailored to clients’ diverse operational needs. Richi’s commitment to excellence extends beyond machinery manufacturing; they provide comprehensive training, maintenance, and technical support to ensure their clients achieve optimal productivity.

Other Prominent Manufacturers: Include La Meccanica (Italy), Yemmak (Turkey), and several other notable companies, each contributing unique strengths to the industry.

How to Choose the Right Wood Pellet Machine?

Selecting a wood pellet machine is a crucial decision that impacts the efficiency and viability of pellet production. Key factors to consider include:

Production Capacity: The machine’s capacity should align with your production goals. High-capacity machines are suited for industrial operations, while smaller ones are adequate for local or community-level production.

Efficiency: Energy consumption and operational efficiency are vital in reducing production costs and environmental impact.

Durability: A durable machine minimizes maintenance costs and downtime, ensuring continuous production.

Customization: Depending on specific needs, some operations may require customized machinery solutions.

After-Sales Support: Reliable after-sales service is essential for the long-term operation of the machinery.

Cost-Effectiveness: Consider both the initial investment and long-term operational costs.

The Benefits of Choosing Richi Machinery

Opting for Richi Machinery offers a range of benefits:

Customized Solutions: Richi specializes in providing machines tailored to specific operational requirements, ensuring optimal productivity.

Quality and Durability: Their machinery is built for longevity, offering consistent performance and reducing the need for frequent repairs.

Technological Advancement: Richi stays ahead of industry trends, incorporating the latest technologies into their products for superior performance.

Exceptional Customer Support: Known for their comprehensive customer service, Richi ensures clients have the support they need, from installation to maintenance.

The wood pellet machinery industry, thriving from 2019 to 2023, underscores the global shift towards sustainable energy. Manufacturers like Richi Machinery have been instrumental in this evolution, offering innovative, efficient, and eco-friendly solutions.

As the industry progresses, these manufacturers will continue to play a vital role in meeting the world’s renewable energy needs, with Richi Machinery leading the way in customer satisfaction and technological innovation.